- 您现在的位置:买卖IC网 > Sheet目录240 > PAXLIT00 (Red Lion Controls)METER AC CURRENT 5A 3 1/2-DIGIT

�� �

�

�

�3.0� W� IRING�

�THE�

�M� ETER�

�WIRING� OVERVIEW�

�Electrical� connections� are� made� via� screw-clamp� terminals� located� on� the�

�back� of� the� meter.� All� conductors� should� conform� to� the� meter� ’s� voltage� and�

�current� ratings.� All� cabling� should� conform� to� appropriate� standards� of� good�

�installation,� local� codes� and� regulations.� It� is� recommended� that� power� supplied�

�to� the� meter� (AC)� be� protected� by� a� fuse� or� circuit� breaker.�

�When� wiring� the� meter,� compare� the� numbers� embossed� on� the� back� of� the�

�meter� case� against� those� shown� in� wiring� drawings� for� proper� wire� position.� Strip�

�the� wire,� leaving� approximately� 0.3"� (7.5� mm)� bare� lead� exposed� (stranded� wires�

�should� be� tinned� with� solder.)� Insert� the� lead� under� the� correct� screw-clamp�

�terminal� and� tighten� until� the� wire� is� secure.� (Pull� wire� to� verify� tightness.)�

�EMC� INSTALLATION� GUIDELINES�

�Although� this� meter� is� designed� with� a� high� degree� of� immunity� to� Electro-�

�Magnetic� Interference� (EMI),� proper� installation� and� wiring� methods� must� be�

�followed� to� ensure� compatibility� in� each� application.� The� type� of� the� electrical�

�noise,� its� source� or� the� method� of� coupling� into� the� unit� may� be� different� for�

�various� installations.� Listed� below� are� some� EMC� guidelines� for� successful�

�installation� in� an� industrial� environment.�

�1.� The� meter� should� be� mounted� in� a� metal� enclosure,� which� is� properly�

�connected� to� protective� earth.�

�2.� Never� run� Signal� or� Control� cables� in� the� same� conduit� or� raceway� with� AC�

�power� lines,� conductors� feeding� motors,� solenoids,� SCR� controls,� and�

�heaters,� etc.� The� cables� should� be� run� in� metal� conduit� that� is� properly�

�grounded.� This� is� especially� useful� in� applications� where� cable� runs� are� long�

�and� portable� two-way� radios� are� used� in� close� proximity� or� if� the� installation�

�is� near� a� commercial� radio� transmitter.�

�3.� Signal� or� Control� cables� within� an� enclosure� should� be� routed� as� far� away� as�

�possible� from� contactors,� control� relays,� transformers,� and� other� noisy�

�components.�

�4.� In� extremely� high� EMI� environments,� the� use� of� external� EMI� suppression�

�devices,� such� as� ferrite� suppression� cores,� is� effective.� Install� them� on� Signal�

�and� Control� cables� as� close� to� the� unit� as� possible.� Loop� the� cable� through� the�

�core� several� times� or� use� multiple� cores� on� each� cable� for� additional� protection.�

�Install� line� filters� on� the� power� input� cable� to� the� unit� to� suppress� power� line�

�interference.� Install� them� near� the� power� entry� point� of� the� enclosure.� The�

�following� EMI� suppression� devices� (or� equivalent)� are� recommended:�

�Ferrite� Suppression� Cores� for� signal� and� control� cables:�

�Fair-Rite� #� 0443167251� (RLC� #FCOR0000)�

�TDK� #� ZCAT3035-1330A�

�Steward� #28B2029-0A0�

�Line� Filters� for� input� power� cables:�

�Schaffner� #� FN610-1/07� (RLC� #LFIL0000)�

�Schaffner� #� FN670-1.8/07�

�Corcom� #1VR3�

�Note:� Reference� manufacturer� ’s� instructions� when� installing� a� line� filter.�

�5.� Long� cable� runs� are� more� susceptible� to� EMI� pickup� than� short� cable� runs.�

�Therefore,� keep� cable� runs� as� short� as� possible.�

�6.� Switching� of� inductive� loads� produces� high� EMI.� Use� of� snubbers� across�

�inductive� loads� suppresses� EMI.�

�Snubber:� RLC#SNUB0000.�

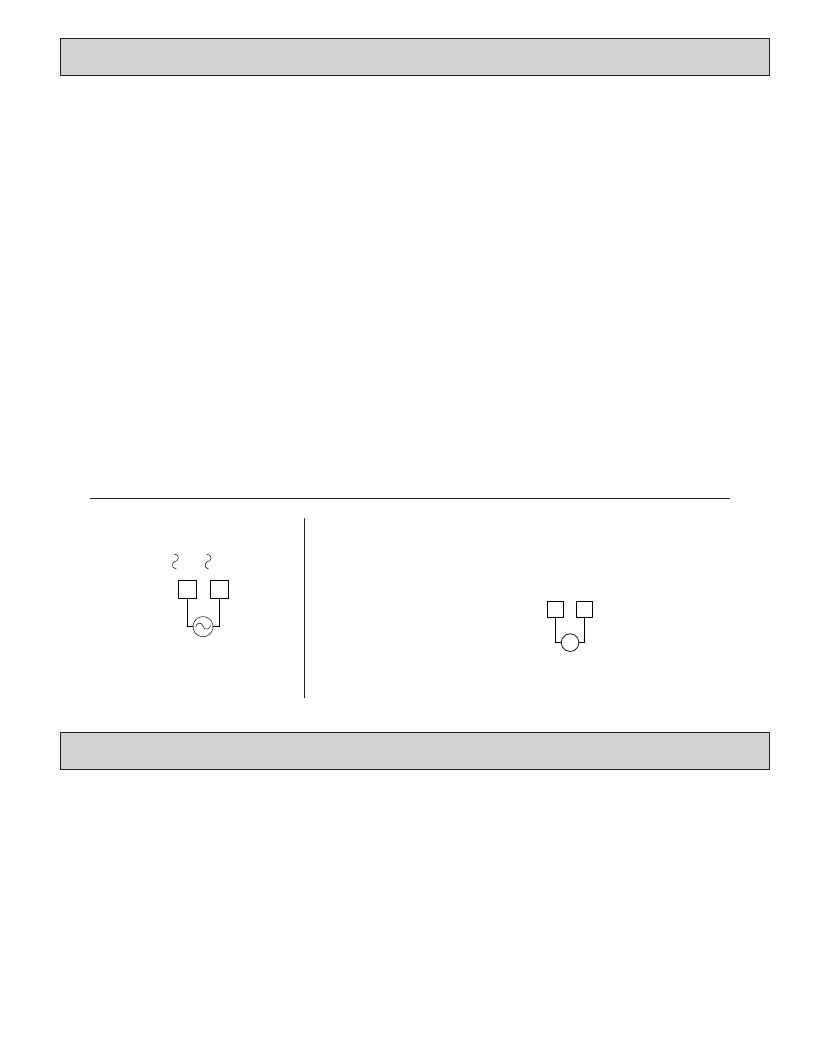

�3.1� POWER� WIRING�

�AC� Power�

�Terminal� 1:� VAC�

�3.2� INPUT� SIGNAL� WIRING�

�Current� Signal� (self� powered)�

�Terminal� 4:� +� Amps� AC�

�Terminal� 2:� VAC�

�1�

�2�

�Terminal� 3:� -� Amps� AC�

�3�

�4�

�115/230�

�-�

�A�

�+�

�5A� MAX.�

�4.0� S� CALING�

�THE�

�M� ETER�

�FACTORY� SCALING�

�The� meter� is� calibrated� from� the� factory� for� 5� Amps� AC� current� input� to� show�

�1999.� This� scaling� will� be� used� when� the� Scale� Switch� is� in� the� “OFF”� position.�

�5�

�SCALING� READOUT�

�Place� the� Scale� Switch� in� the� “ON”� position.� This� enables� the� Scale�

�Potentiometer� which� is� accessible� from� the� back� of� the� meter.� (Enabling� the�

�Scale� Potentiometer� does� NOT� affect� the� calibration� of� the� meter.)� Place� the�

�Decimal� Point� Switches� to� the� proper� location.� Apply� the� meter� power� and� the�

�current� signal.� Adjust� the� Scale� Potentiometer� to� the� desired� value.�

�This� scaling� only� effects� the� span.� There� is� no� offset� scaling.� This� means� that�

�only� zero� current� can� display� a� value� of� zero.�

�At� 5� Amps� AC� current� input,� the� display� can� be� scaled� from� 1999� down� to�

�200� by� using� the� scaling� potentiometer.� For� display� values� below� 200,� turn� on�

�the� appropriate� Decimal� Point� Switch� and� then� adjust� the� potentiometer� to�

�achieve� the� desired� display� value.� Example:� A� customer� wants� to� display� 50�

�Amps� because� he� is� using� a� 50:5� CT.� In� this� case,� he� must� turn� DIP� switch� 1� on�

�for� a� decimal� point� and� DIP� switch� 5� on� for� scaling.� Then� apply� the� 5� Amp�

�signal� and� turn� the� scaling� pot� until� 50.0� is� shown� on� the� display.�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

PAXLPV00

METER PROCESS VOLT 3 1/2-DIGIT

PAXLRT00

METER RTD TEMP 4-DIGIT

PAXLSG00

METER STRAIN GAGE 3 1/2-DIGIT

PAXLTC00

METER THERMOCOUPLE 4-DIGIT

PAXLVA00

VOLTMETER AC 3 1/2-DIGIT

PAXLVD00

VOLTMETER DC 3 1/2-DIGIT

PAXTM100

TIMER DISPLAY 1/8 DIN PRESET 6 D

PB-1583-TF

BOX ABS 4.37X3.12X2" BK 1=10PCS

相关代理商/技术参数

PAXLPT00

功能描述:METER PROCESS TIME 6-DIGIT RoHS:是 类别:工业控制,仪表 >> 定时器 系列:PAX®LITE 标准包装:10 系列:- 计时范围:- 工作模式:累积 输出类型:- 电源电压:4.5 V ~ 10 V 端接类型:PCB 引脚 显示器类型:无显示器 其它名称:2001PC-001 5VDCQ1273012Q1443992

PAXLPV00

功能描述:METER PROCESS VOLT 3 1/2-DIGIT RoHS:否 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXLR000

功能描述:METER RATE INDICATION 6-DIGIT RoHS:是 类别:工业控制,仪表 >> 计数器 系列:PAX®LITE, PAXLR 其它有关文件:Declaration of Conformity 标准包装:1 系列:99766 计数速率:25Hz 数字/字母数:5 输入类型:机电式脉冲 输出类型:- 电源电压:24V 显示器类型:十进制拨轮

PAXLRT00

功能描述:METER RTD TEMP 4-DIGIT RoHS:是 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXLSG00

功能描述:METER STRAIN GAGE 3 1/2-DIGIT RoHS:否 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030

PAXLT000

制造商:Red Lion Controls 功能描述:METER, TC/RTD TEMP WITH DUAL RELAY 制造商:Red Lion Controls 功能描述:TC/RTD TEMP WITH DUAL RELAY

PAXLT0U0

制造商:Red Lion Controls 功能描述:METER, UL LISTED TC/RTD TEMP W/ D RELAY 制造商:Red Lion Controls 功能描述:UL LISTED TC/RTD TEMP WITH DUAL

PAXLTC00

功能描述:METER THERMOCOUPLE 4-DIGIT RoHS:否 类别:工业控制,仪表 >> 仪表 - 面板,数字 系列:PAX®LITE 标准包装:12 系列:* 其它名称:Q7072030